Article of the Month -

July 2011

|

Spatially Smart Wine – Testing Geospatial Technologies for Sustainable

Wine Production

Kate FAIRLIE, Mark WHITTY, Mitchell LEACH, Fadhillah

NORZAHARI, Adrian WHITE, Stephen COSSELL, Jose GUIVANT and Jayantha

KATUPITIYA, Australia

This article in .pdf-format

(20 pages, 2,86 MB)

This article in .pdf-format

(20 pages, 2,86 MB)

1) Among the authors from our paper

of the month July 2011 5 are part of the Sydney Young Surveyors group.

Kate Fairlie is at the same time also Chair of the FIG Young

surveyors network. “Spatially Smart Wine” was a project initiated

by an enthusiastic group of Sydney Young Surveyors, with the support of

the Institute of Surveyors New South Wales and the School of Surveying

and Spatial Information Systems and the University of New South Wales.

In this research geospatial technologies are evaluated for precision

viticulture, supporting organic and biodynamic principles. The vineyard

application is demonstrated of a teleoperated vehicle with three

dimensional laser mapping and GNSS localisation to achieve

centimetre-level feature position estimation.

Key words: Precision viticulture, Unmanned Ground

Vehicles, LiDAR, young surveyors

SUMMARY

Sustainable agriculture to feed a growing population is

one of the world’s critical challenges. In smaller scale farms, such as

vineyards, a key research question is how to achieve consistent,

optimised yields to minimise artificial system inputs and environmental

damage.

In this research, we evaluate geospatial technologies

for precision viticulture, supporting organic and biodynamic principles.

We demonstrate the vineyard application of a tele-operated vehicle with

three dimensional laser mapping and GNSS localisation to achieve

centimetre-level feature position estimation.

Precision viticulture is not a new concept, having evolved from

precision agriculture in the 1990s. Geospatial technologies have much to

contribute to this field, with smaller scale vineyards requiring

customisable applications and high precision positioning. Sustainable

farming practices, including organic and biodynamic principles, further

require the integration of multiple layers of spatial information to

optimise yield and achieve long term sustainable outcomes. Key

applications for geospatial data include tailored multi-layer farm maps

(information systems), variable mulching, irrigation, spraying and

harvesting.

Technologies evaluated in this project include

multi-layered information systems, GNSS receivers, Continuously

Operating Reference Stations (CORS) and related hardware – with the

integration of technologies and farmer usability key considerations. We

also test the University of New South Wales Mechatronics Unmanned Ground

Vehicle (UGV) in the vineyard. This vehicle generates georeferenced

point clouds in real-time while being tele-operated through the

vineyard. A major feature of this vehicle's sensors is the use of

off-the-shelf hardware, allowing it to be retrofitted to existing

vehicles of any scale. The accuracy of the generated point clouds is

calculated and compared with that obtained from aerial LiDAR. Automation

of existing actuators for controlling yield-dependent variables such as

mulching and irrigation via feedback from the combined sources of data

is clearly the future of precision viticulture. The end product?

Spatially smart wine.

1. INTRODUCTION

1.1 Precision Viticulture

Precision viticulture (PV) is styled from the zonal

management paradigm of precision agriculture, where large homogeneous

fields are divided into smaller units based on yield or other field

characteristics which may be differentially managed (Lamb et al., 2002,

Bramley, 2009, Bramley and Robert, 2003) (note that McBratney et al.

(2005) suggest the definition of precision agriculture is continually

evolving as we develop further technologies and greater awareness of

agricultural processes). PV acknowledges the numerous spatial variations

that affect grape quality and yield, including soil characteristics,

pests and diseases and topography (Hall et al., 2003, Arnó et al.,

2009), providing land managers with the tools to quantify and manage

this variability (Proffitt, 2006). Land managers can thus ‘selectively’

treat areas, for example by the variable application of mulch, water,

fertiliser, sprays etc.

The general process of PV is cyclical across

observation, evaluation and interpretation - which informs a targeted

management plan followed by ongoing observation and evaluation (Bramley

et al., 2005). The benefits of PV are increased knowledge of vineyard

processes, allowing for targeted improvements to yield, wine quality,

reduced disease incidence and increased resilience across the vineyard

(Johnson et al., 2003). Data capture undertaken as part of PV can inform

mechanised operations for greater efficiency in irrigation, spraying,

mulching and pruning, and selective harvesting. Decision support systems

are further supported and may aid land managers when in the field

(Johnson et al., 2003). PV mitigates against the growing problems of

climate change (Battaglini et al., 2009, Shanmuganthan et al., 2008),

food security (Gebbers and Adamchuk, 2010) and supports the growing

awareness of the consumer and market demands (Delmas and Grant, 2008,

Rowbottom et al., 2008, Chaoui and Sørensen, 2008).

Research into the use of autonomous machinery in vineyards is still

young and presents opportunities for further development (Grift et al.,

2008, Longo et al., 2010). The use of wireless sensor networks is a

recent addition to PV, but not yet routinely implemented (see examples

in Shi et al., 2008, Matese et al., 2009, López Riquelme et al., 2009,

Morais et al., 2008). A significant limitation of current applications

and research is the lack of an appropriate, multi-functional decision

support system (McBratney et al., 2005, Arnó et al., 2009).

This research focuses on the contribution of surveying

and spatial technologies to PV, with a focus on sensor applications for

tele-operated and autonomous machinery. This paper reports the

preliminary findings of a scoping fieldtrip, with an outline of

technologies tested for their utility and suitability to the client’s

needs.

1.2 The ‘Spatially Smart Wine Project’

‘Spatially Smart Wine’ is a joint initiative of the

International Federation of Surveyors (FIG) Young Surveyors Network, the

New South Wales Institution of Surveyors Young Surveyors Group

(Australia) and the University of New South Wales Schools of Surveying

and Mechatronic Engineering. The project was initiated to improve the

networks and skills of young surveyors in the Sydney region, and to

generally improve community understanding of surveying (see Figure 1).

Additional benefits are increasing surveyors’ knowledge of PV!

|

Figure 1: The authors at Jarrett's Vineyard |

General details of how the project was run are reported in

Fairlie and McAlister (2011). Fieldwork was undertaken at

Jarrett’s wines, a small to medium (300 hectare) vineyard 30km

south west of Orange, NSW, Australia – approximately 300km west

of Sydney. Established just over 15 years ago, the management of

the vineyard now incorporates organic and biodynamic farming

principles. The vineyard manager sees PV as a critical element

of sustainable vineyard management. Biodynamic viticulture

rejects the use of synthetic chemical fertilisers and

pesticides. Both organic and biodynamic farming practices

embrace the use of natural products, but the underlying

philosophy of biodynamics is the use of soil and plant

‘preparations’ to stimulate the soil and enhance plant health

and product quality (Reeve et al., 2005). |

The adoption of organic and/or biodynamic farming

practices is likely to increase with greater awareness of climate change

and sustainability requirements (Turinek et al., 2009). The general

thesis of these farming processes is sustainable agriculture, with no

long term environmental damage. There remain a number of research gaps

in organic and biodynamic farming practices – for example, critics cite

a lack of scientific understanding and rigour within the biodynamic

field (Kirchmann, 1994) . PV technology has a role to assist, for

example in research on soil nutrient variability, mapping and

management, weed control, and achieving dual outcomes of economic and

environmental sustainability. Research is advancing with regards to

robotic weeders, online systems to manage soil nutrients and crops, but

commercial adoption and availability of products is limited (see

Dedousis et al., 2010 for an overview of the field). The general goal of

the fieldwork was the testing of survey and spatial technologies for PV,

particularly taking into account client needs and fitness-for-purpose.

1.3 Outline of this paper

In the following sections we will provide an overview of

surveying technologies applicable to PV, an initial high level

qualitative analysis of technologies tested, and finally an overview of

the outputs and accuracies achieved in uniting the Unmanned Ground

Vehicle with surveying technologies.

2. APPLICATION OF SURVEYING TECHNOLOGIES TO PRECISION

VITICULTURE

PV requires much finer sampling than precision

agriculture (Bramley and Janik, 2005), hence the greater need for

surveying and spatial professionals to engage with this industry.

Viticulture is particularly suited to spatial and surveying

technologies, due to the ‘fixed’ nature of plantings and the perennial

nature of crops (Arnó et al., 2009) and spatial analysis is critical to

managing vineyard productivity and minimising risk in small scale

vineyards.

Vineyard establishment in Australia will typically

involve soil sampling (including type mapping, salinity measurements and

moisture distribution), topographic mapping and surveyor set-out of

plantings, with grape varieties located according to appropriate soil

type, nutrient and moisture levels. Topographic variation is a critical

driver of vineyard yield variation (see Bramley 2006, Bramley and

Williams 2007), particularly in the Australian case where yield is

closely linked to water supply and generally varies with topography

(Bramley 2003b).

Once established there are a number of ongoing roles for

spatial data and analysis. Vineyard leaf area is a key determinant of

grape characteristics and wine quality and is a predictor of fruit

ripening rate and instances of infestation and disease. Vineyard leaf

area measurements can inform pruning procedures, shoot thinning, leaf

removal and irrigation (Johnson et al., 2003). International monitoring

of emissions for climate change mitigation and adaptation is further

creating a role for spatial technology in the vineyard. Transient

biomass (changes in biomass from year to year) provides an indication of

the most productive areas of the vineyard, and monitoring of biomass may

be a future requirement of climate change policy. Measurement of

transient biomass year by year (i.e. following pruning) is common, but

difficult and expensive – remote imaging options present much more

efficient forms of measurement (Keightley and Bawden, 2010). Uniquely,

Mazzetto (2010) present a ground-based mobile remote sensing lab to

allow more frequent and targeted vineyard spatial analysis.

Table 1 provides an overview of sensor technologies for

PV and their applications and benefits.

|

Sensor/ Technology |

Application |

Benefits |

|

Aerial LiDAR and Terrestrial laser scanning |

- Measurement of

tree/vine trunk diameter

- Height of vegetation and topography

- Leaf area density and index

- 3D reconstruction of vegetation/objects |

- Carbon measurement: wood volume of perennial crops

indicative of carbon storage (Keightley and Bawden, 2010)

- Foliage density and height for variable spray applications

(Gil, 2007, Rosell et al., 2009, Rosell Polo et al., 2009) |

|

Satellite/aerial multi- and hyper- spectral imagery |

- Selective harvesting

- Yield estimation

- Digital Terrain Model

- Soil information

- Crop vigour indices (such as Normalised Difference

Vegetation Index (NDVI), Leaf area index (LAI)) |

- Topography provides indication of water/soil variation

(Bramley, 2009, Bramley and Robert, 2003, Lamb et al., 2002)

- Healthy, vigorous grapevines typically have higher

reflectivities (Arnó et al., 2009). Leaf density has been

shown to be linked to grape yield and quality (Lamb et al.,

2002). NDVI measurements can identify downy mildew (Mazzetto

et al., 2010)

- LAI is related to fruit ripening rate, so can be used to

parameterise plant growth models and for decision support

systems (Johnson, 2003). LAI can also inform spraying

(Siegfried et al., 2007) |

|

Ground Penetrating Radar (GPR) |

- Soil water content |

- Soil water content informs planting and vineyard

management (Grote et al., 2003) |

|

Tele-operated and autonomous machinery applications |

- Mulching, irrigation, spraying, harvesting etc. |

- Relieves staff workload and allows for supported decision

making, such as real-time measurement and resultant

variability in applications (see for example, Bramley et

al., 2005) |

|

GPS |

- Accurate location of position

- GPS data can be incorporated into maps, giving new

interpretative power to generate more meaningful maps |

- The accessibility and low cost of GPS means that

grape-growers can accurately locate themselves within their

vineyard when sampling for vine growth, development and

productivity (Lamb et al., 2002) |

|

GPS- and GIS-enabled Toughbook |

- Data collection of location of vines posts, quality of

vines, defects (destroyed vines etc), rabbit holes etc |

- Cost-effective and convenient for basic mapping and data

collection, replacing the traditional pen and paper-based

method (Koostra et al., 2003) |

Table 1 : Surveying technologies

and their applications to PV. Compiled from (Keightley and Bawden, 2010,

Bramley, 2009, Bramley and Robert, 2003, Lamb et al., 2002, Grote et

al., 2003, Bramley et al., 2005) Note the focus of this table is on

technologies traditionally associated with the geospatial and surveying

professions. It does not represent an exhaustive list of sensor

technologies used in precision viticulture.

3. TESTING OF GEOSPATIAL TECHNOLOGIES – DISCUSSION

3.1 Status of the vineyard

Jarrett’s wines, the subject location of this study, had

undertaken much of the above however it soon became apparent that data

was poorly managed, with a mix of hard- and soft-copy data. The

importance of spatial data management is rarely reported in the PV

literature, and the ad hoc nature of spatial data acquisition and

surveyor involvement limits the opportunities for an efficient spatial

data management system to be implemented.

User defined needs and goals are critical to spatial planning, and on

discussion with the vineyard owner the following needs were identified:

-

Short-term: Interactive map of the farm, to include

collated and digitised hardcopy data, to be updatable, portable and

easy for all staff to use;

-

Long-term: GNSS- and sensor- enabled machinery to

facilitate variable application of mulch, irrigation and sprays;

-

Ongoing: Develop knowledge of the vineyard,

including vine mapping, identification of yield and foliage density

etc. to inform pruning and harvesting.

3.2 GNSS equipment

A selection of GNSS-enabled equipment was tested on site

to determine its suitability for operational use in a vineyard,

including:

-

Getac Toughbook (rugged tablet computer), with ESRI

ArcPad (Provided by ESRI Australia)

-

Leica Zeno (handheld, differential GPS).

(Provided by CR Kennedy)

-

Leica Viva (RTK with solutions up to 2cm)

(Provided by NSW Land and Property Management Authority)

In order to achieve Differential GPS and RTK solutions,

correction data from CORSnet-NSW, the New South Wales government funded

Continuously Operating Reference Station (CORS) network, was utilised.

The closest CORS was Orange (approximately 30km from site), although

virtual base DGPS solutions, Virtual Reference Station (VRS) and Master

Auxiliary Concept (MAC) solutions provided through the network were also

tested.

The vineyard manager was present at testing, and

provided valuable insight into the suitability and application of these

technologies to the vineyard. We will examine each technology and its

application in the vineyard in the following subsections.

3.2.1 Getac Toughbook with ESRI ArcPad

Large amounts of data are associated with PV. Given the

surveyor cannot remain on hand, vineyard managers need to be able to

easily create, store and retrieve spatial data. Handheld computers are

cost-effective and convenient for basic mapping and data collection

tasks commonly performed for precision agriculture practices (Koostra et

al, 2003).

The Getac Toughbook is both GIS- and GPS-enabled. Note

that not all Toughbooks are GPS-enabled, but GPS add-ons are easily

attainable. In this case study, the vineyard manager had recently

purchased a Toughbook, deeming it necessary for day-to-day tasks within

the vineyard including the onsite viewing of spatial data, tracking of

tasks and identification of follow-up areas. For example, vineyard

inspections to identify follow-up locations for pest and weed treatment,

or localised incidents of vine disease.

For efficient and integrated use (i.e. across multiple

computers and personnel) some form of mapping software is a requirement.

ESRI’s ArcPad was used in this field test, but it is by no means the

only, or necessarily the best option. Advanced spatial users can easily

develop mapping applications, mashups and queries to best inform

vineyard decision making, using either ESRI, open source or other

applications. This is identified as a significant market area for

further development as no immediate, easy-to-use and off-the-shelf

options are known to the authors. Wireless connectivity between hardware

is a further option under consideration on the farm.

Problems observed in the field using the Toughbook

include difficulties of use in bright sunlight, screen size and

intuitiveness to users not accustomed to spatial data. There was a need

for better accessories to ease its utility in the field (e.g. vehicle

and personal holders and data entry tools). GPS and CORS were deemed

critical enablers for in the field applications.

3.2.2 Leica Zeno handheld DGPS, ESRI ArcPad enabled

The Leica Zeno is marketed as the ‘most rugged and

versatile GNSS/GIS handheld in the market’(Leica Geosystems, 2009). The

Zeno provides a differential correction to the GPS coordinates which

would allow operators to easily determine the specific row and vine for

follow up inspections.

The Leica Zeno used in the pilot project also had ESRI

ArcPad installed on it. We found the Zeno to be more suited to users

with a spatial background as it has functionalities (e.g. DGPS

capabilities) that can be easily understood by a spatial-user and vice

versa. The Toughbook on the other hand has limited high-accuracy

surveying capabilities, thus making it easier to use and therefore

suitable for non-spatial users.

3.2.3 Leica Viva RTK

RTK solutions were found to primarily support the

implementation of machine guidance operations. For the efficient

operation of auto-steered machinery, as discussed in the following

section, key aspects (especially obstacles) of the vineyard would need

to be mapped to a high level of accuracy. Auto-steer technologies would

then use RTK position solutions, with operator alerts if the machinery

began to run off-centre due to degradation of the RTK signal or other

problem such as close proximity to buildings and trees due to multipath.

With all three technologies having useful application

within the vineyard it is evident that an integrated data management

system would be highly beneficial. A decision support system can be used

and integrated with the process model to represent the use of

information (Smith et al., 1998). With wireless connectivity available

on all three devices this management system need not be provided by the

vineyard but is possible through broader precision agriculture support

services. It is in this area that significant research and development

can still take place to value-add on the implementation of positioning

and guidance technologies in the vineyard. The Australian government

announcement of a National Broadband Network is also expected to further

this research area.

3.3 ESRI’s ArcPad

ArcPad is ESRI’s solution for database access, mapping,

GIS, and GPS integration on handheld and mobile devices (ESRI 2002). The

most salient feature of ArcPad for our purposes is the ability to

customise by:

-

Designing forms for more efficient data collection,

-

Writing scripts for more efficient, user-friendly

analysis, and

-

Building applets that customise a collection of

tools and scripts.

A chief concern with the use of ESRI’s ArcPad is the

licence cost and user training needs. The above features would need to

be set up by a more experienced spatial professional. A number of

alternative GIS and spatial data display/management systems exist, but

testing these is beyond the scope of this paper (http://opensourcegis.org

details many alternative options. Google Earth is a familiar option that

many lay users would find easy to adopt).

3.4 LiDAR Technology

LiDAR (Light Detection And Ranging) is an optical remote

sensing technology which is used to measure properties of scattered

light to find range, elevation and other information of a distant

target. It records not only the multi-reflection laser pulses that

return from the object but the intensity information for each returned

laser pulse. The LiDAR system is widely used in geoinformatics,

archaeology, geography, geology, geomorphology, seismology, remote

sensing and atmospheric physics (Cracknell et al, 2007).

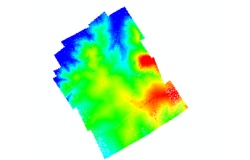

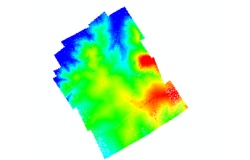

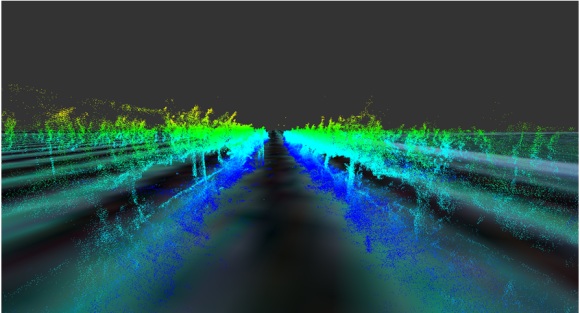

Aerial LiDAR data was gathered during a flight over the

vineyard (LiDAR was flown over the area by the NSW Land and Property

Management Authority for calibration purposes of their newly acquired

aircraft) and Figure 3 shows the resulting aerial point cloud.

Figure 2 shows a subset of the points overlaid on aerial imagery. The

LiDAR imagery was obtained for a terrain map of the area of study. It

was envisaged that LiDAR technology may improve understanding of

vineyard processes and foliage density, which would help develop

precision pruning and harvesting of future crops. The vineyard manager

already had a time series of multispectral aerial imagery data (as a

general indication, Bramley (2009) reports the cost of multispectral

imagery at AUD$30/ha), and LiDAR imagery was deemed to further

augment this. It is estimated that the cost of aerial-LiDAR to be around

AU$3000 for the survey of the vineyard.

|

Figure 3: Point-cloud data of

aerial-LiDAR over the Jarrett's Wines vineyard |

Figure 2: Aerial LiDAR overlaid on aerial photograph |

3.4.1 Data Specification/Description

|

Table 2: General specifications of aerial-LiDAR

data (LPMA, 2010) |

|

Horizontal Datum |

GDA94 |

|

Vertical Datum (Orthometric) |

AHD71 |

|

Vertical Datum (Ellipsoidal) |

ITRF05 |

|

Projection |

MGA Zone 55 |

|

Geoid |

AUSGeoid09 |

|

Metadata |

ANZLIC Metadata Profile Version 1.1 |

|

|

|

Table 3: Five classification levels of

aerial-LiDAR data (LPMA, 2010) |

|

Level |

Description |

|

0 |

Unidentified |

|

1 |

Automated Classification |

|

2 |

Ground Anomaly Removal |

|

3 |

Manual Ground Correction |

|

4 |

Full Classification |

|

Note: The classified point cloud is also retained

in its primary ellipsoid height format so as to allow for future

improvements in the vertical datum and to enable accurate nesting of

adjacent elevation data

3.4.2 LiDAR Analysis

The LiDAR was flown, analysed and processed by the Land,

Property and Management Authority (LPMA) in Bathurst (see Table 2 for

specifications). Data was predominantly processed using TerraMatch and

TerraScan MicroStation plug-ins. In addition to that, the plug-in LP360

by QCoherent was also used to check data quality and to verify the

processed (final) LAS files. TerraMatch was used to apply corrections

and changes to the LAS files based on (1) heading, (2) roll, (3) pitch,

(4) mirror scale and (5) z-shift (elevation) of the points captured

based on the movement of the plane relative to the point-capture

exercise.

The LiDAR datasets were classified according to the

“spatial accuracy” of the data. Once a LiDAR survey is determined to be

“spatially accurate”, any remaining significant errors in the data are

likely to be the result of incorrect classification. For example in

wetland areas, due to the lack of actual ground strikes, dense

vegetation is often classified as ground by the automated algorithms. A

significant amount of manual effort is then required to correct the

classification attributes (LPMA, 2010). Table 3 briefly outlines the

five classification levels as defined by the LPMA. The levels are

allocated by the various automated and manual processes. Successive

level reflects increasing classification completeness and effort. For

the purpose of this project, the aerial LiDAR data has been processed to

Level 2 standards, where the anomalies found in the ground data were

removed to create a ground surface suitable for ortho-rectification of

imagery with minimum effort (LPMA, 2010).

3.4.3 LiDAR Accuracy

The following discussion on LiDAR accuracy is based on

the LPMA standards for processing aerial-LiDAR data (This section is

an excerpt from the LPMA Standard LiDAR Product Specifications, Version

2.0, July 2010).

Vertical accuracy is assessed by comparing LiDAR point

returns against survey check points on bare open ground. It is

calculated at the 95% confidence level as a function of vertical RMSW

(as per ICSM Guidelines for Digital Elevation Data 2008 - retrieved

online from the ‘Intergovernmental Committee on Surveying & Mapping’

(ICSM) website -

http://www.icsm.gov.au/icsm/elevation/ICSM-GuidelinesDigitalElevationDataV1.pdf).

This is undertaken after the standard relative and absolute adjustment

of the point cloud data has taken place (i.e. flight line matching and

shift/transformation to local AHD).

Horizontal accuracy is checked by comparing the LiDAR

intensity data viewed as a “TIN” surface against surveyed ground

features such as existing photo point targets. To date our analysis of

ground comparisons shows that although the vertical accuracy achieved on

bare open ground is well within the requirements for Category 1 Digital

Elevation Model (DEM) products as specified in the ICSM Guidelines for

Digital Elevation Data, local geoid and height control anomalies may

degrade the accuracy on large coastal projects.

|

Vertical accuracy |

±30cm at 95% confidence (1.96 x RMSE) |

|

Horizontal accuracy |

±80cm at 95% confidence (1.73 x RMSE) |

3.4.4 Advantages and Disadvantages of LiDAR

Technology

Advantages of LiDAR include the high data accuracy,

large area coverage and quick data turnaround. The cost is small

compared with the acquisition of similar accuracy level data using a

team of surveyors and total stations (Note the authors did not pay

for the LiDAR data collection in this analysis. An estimated cost was

provided by the LPMA, a government department, of around AU$3000 for the

300ha vineyard. As a general comparison, Bramley (2009) reports the cost

of multispectral imagery at AUD$30/ha, however prices are decreasing at

a rapid rate).

Disadvantages include the weather-dependence of LiDAR,

and the inability of LiDAR to penetrate dense canopies (such as vines

during harvest season), thus preventing the creation of accurate DEMs.

Canopy imaging does, however, present a further opportunity for LiDAR

applications (see Table 1), however more research is required and it may

be possible to derive the same benefits from terrestrial applications

(see Section 4.5, Table 5 for a comparison of aerial and terrestrial

LiDAR solutions).

4. UNMANNED GROUND VEHICLE (UGV): TESTING AND

APPLICATIONS

|

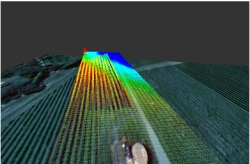

Here we present an Unmanned Ground Vehicle (UGV)

which contains technologies for automated yield estimation which

are readily applicable to many existing agricultural machines.

The UGV was developed in the School of Mechanical and

Manufacturing Engineering at the University of New South Wales

under the direction of Associate Professor Jayantha Katupitiya

and Dr Jose Guivant. As shown in Figure 4, it is a four wheeled

vehicle equipped with sensors and actuators for tele-operation

and full autonomous control. Weighing 50kg, it is a comprised of

Commercial-Off-the-Shelf (COTS) sensors, a custom-made

mechanical base and a low-cost onboard laptop with a wireless

connection to a remote Base Station (BS). Of particular note is

ready retrofitting capacity of the COTS sensors to existing farm

machinery.

For the purposes of this paper, the vehicle was tele-operated

from the nearby BS with the operator manoeuvring with the aid of

three onboard video cameras and a display of the LiDAR data in

real-time. Autonomous operation using the LiDAR data and was

demonstrated in Whitty et al. (2010) . For videos, see our

YouTube channel:

www.youtube.com/UNSWMechatronics |

4.1 System Overview

The equipment contained in the vehicle is shown in Table

4. Of this the relevant items are the rear 2D LiDAR sensor, the IMU, the

CORS-corrected GPS receiver and the wheel encoders. Together with the

onboard computer, these items allow accurate georeferenced point clouds

to be generated which are accurate to 8cm. The output is not limited to

point clouds, as any other appropriately sized sensors can be integrated

to provide precise positioning of the sensed data, either in real-time

or by post-processing.

|

Device |

Manufacturer |

Purpose |

|

LiDAR sensor |

SICK |

Measures range and bearing to a set of points |

|

Inertial Measurement Unit (IMU) |

Microstrain |

Measures roll, pitch and yaw angles and rates |

|

Wheel encoders |

Maxon |

Measures wheel position and velocity |

|

GPS receiver |

Leica Geosystems |

Measures GPS position and accuracy |

|

Laptop |

MSI |

Record and process data and communicate with BS |

|

Wifi router |

Meshlium |

Communication with BS |

|

Cameras |

Logitech |

Visual feedback to operator |

Table 4: UGV Equipment

4.2 Measurement Estimation and Accuracy

The following paragraphs show how the pose of the robot

is accurately estimated and then how this pose is fused with the laser

data to obtain 3D point clouds. Given the uncertainty of the robot pose,

we also derive expressions for the resultant uncertainty of each point

in the point cloud. Furthermore, the average case accuracy is compared

with that obtained from aerial LiDAR and the advantages and

disadvantages of both methods of data gathering are discussed from the

perspective of PV.

As presented in Section 3.2, the CORS-linked GPS sensor

mounted on the UGV provides both the position and position uncertainty

of the vehicle in ECEF coordinates. In this case the MGA55 frame was

used to combine all the sensor data for display in one visualisation

package. The GPS position was provided at 1Hz and given the high

frequency dynamics of the robot’s motion, higher frequency position

estimation was necessary. Hence an inertial measurement unit (IMU),

containing accelerometers and gyroscopes, was mounted on the vehicle

providing measurements at 200Hz. The output of this IMU was fused with

the wheel velocities as described in (Whitty et al., 2010) to estimate

the short term pose of the vehicle between GPS measurements. The IMU

also provided pitch and roll angles, which were used in combination with

the known physical offset of the GPS receiver to transform the GPS

provided position to the coordinate system of the robot.

Given the time of each GPS measurement (synchronised

with the IMU readings), the set of IMU derived poses between each pair

of consecutive GPS measurements was extracted. Assuming the heading of

the robot had been calculated from the IMU readings, the IMU derived

poses were projected both forwards and backwards relatively from each

GPS point. The position of the robot was then linearly interpolated

between each pair of these poses, giving an accurate and smooth set of

pose estimates at a rate of 200Hz. Since the GPS measurements were

specified in MGA55 coordinates and the pose estimates calculated from

these, the pose estimates were therefore also found in MGA55

coordinates.

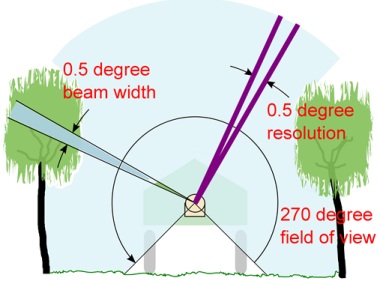

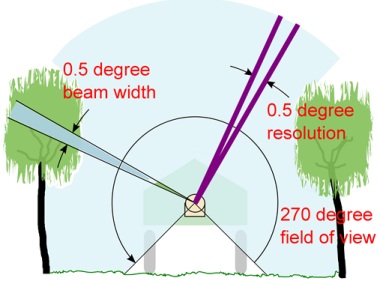

The primary sensor used for mapping unknown environments was the SICK

LMS151 2D laser rangefinder. Figure 6 pictures one of these lasers,

which provided range readings up to a maximum of 50m with a 1σ

statistical error of 1.2cm. Figure 5 shows the Field of View (FoV) as

270° with the 541 readings in each scan spaced at 0.5° intervals and

recorded at a rate of 50Hz, giving about 27 000 points per second. Its

position on the rear of the robot was selected to give the best coverage

of the vines on both sides as the robot moves along a row.

|

Figure 6: LiDAR sensor on the UGV |

Figure 5: 2D Field of View (FoV), showing scan of vines |

To accurately calculate the position of each scanned

point, we needed to accurately determine the position and orientation of

the laser at the time the range measurement was taken. All of the IMU

data and laser measurements were accurately time stamped using Windows

High Performance Counter so the exact pose could be interpolated for the

known scan time. Given the known offset of the laser on the vehicle,

simple geometrical transformations were then applied to project the

points from range measurements into space in MGA55 coordinates. Complete

details are available in Whitty et al., (2010) which was based on

similar work in Katz et al. (2005) and Guivant (2008). This calculation

was done in real-time, enabling the projected points – collectively

termed a point cloud – to be displayed to the operator as the UGV moved.

4.3 Information Representation to Operator

The display of the point cloud was done using a custom built

visualisation program which was also adapted to read in a LiDAR point

cloud and georeferenced aerial imagery obtained from a flight over the

vineyard. Since all these data sources were provided in MGA55

coordinates, it was a simple matter to overlay them to gain an estimate

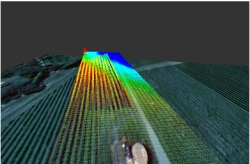

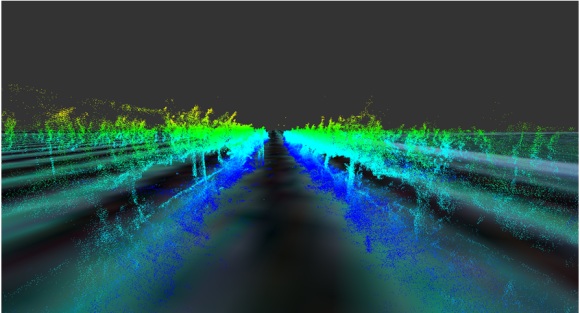

of the accuracy of the laser measurements. Figure 7 shows the

terrestrial point cloud overlaid on the image data where the

correspondence is clearly visible. Given that the point cloud is

obtained in 3D, this provides the operator with a full picture of the

vineyard which can be viewed from any angle.

Figure 7: UGV generated point-cloud with overlay of aerial imagery

4.4 Fusion of Sensor Data and Calculation of Accuracy

Although the above point cloud generation process has

been described in a deterministic manner, in practice measurement of

many of the robot parameters is usually not precise. By performing

experiments, we were able to characterise these uncertainties

individually and then combine them to estimate the uncertainty in

position of every point we measured. In the field of robotics, these

uncertainties are typically characterised as a covariance matrix based

on the standard deviations of each quantity, assuming that they are

normally distributed. The covariance matrix giving the uncertainty of

the UGV’s pose in MGA55 coordinates is a 6x6 matrix. The UGV’s pose

itself is given by a vector which concatenates the 3D position and the

orientation given in Euler angles.

Since the GPS receiver was offset from the origin of the

UGV’s coordinate system, the GPS provided position was transformed to

the UGV’s coordinate system by rigid body transformation. However, the

uncertainty of the angular elements of the pose meant that the GPS

uncertainty must not only be shifted but be rotated and skewed to

reflect this additional uncertainty. An analogy is that of drawing a

straight line of fixed length with a ruler. If you don’t know exactly

where to start, then you have at least the same uncertainty in the

endpoint of the line. But if you also aren’t sure about the angle of the

line, the uncertainty of the endpoint is increased.

A similar transformation of the UGV uncertainty to the

position of the laser scanner on the rear of the UGV provided the

uncertainty of the laser scanner’s position. Then for every laser beam

projected from the laser scanner itself, a further transformation gave

the covariance of the projected point due to the angular uncertainty of

the UGV’s pose.

Additionally, we needed to take into account uncertainty

in the measurement angle and range of individual laser beams. This

followed a similar pattern and the uncertainty of the beam was

calculated based on a standard deviation of 0.5 degrees in both

directions due to spreading of the beam. Once the uncertainty in the

beam, which was calculated relative to the individual beam, was found,

it was rotated first to the laser coordinate frame and then to the world

coordinate frame using the corresponding rotation matrices. Finally, the

uncertainty of the laser position was added to give the uncertainty of

the scanned point.

4.5 Comparison of aerial and terrestrial LiDAR

An experiment was conducted at the location detailed in

Section 1.2. The UGV was driven between the rows of vines to measure

them in 3D at a speed of about 1m/s. The average uncertainty of all the

points was calculated and found to be 8cm in 3D. Table 5 shows how this

compares with about 1.2m for the aerial LiDAR but has the disadvantage

of a much slower area coverage rate. The major advantages however are

the increased density of points (~3000 / m3), ability to scan the

underside of the vines and greatly improved resolution. Also, the

terrestrial LiDAR can be retrofitted to many existing agricultural

vehicles and used on a very wide range of crops. Limited vertical

accuracy – a drawback of GPS – is a major restriction but this can be

improved by calibrating the system at a set point with known altitude.

| |

Units |

Aerial LiDAR |

Terrestrial LiDAR |

|

Sensor |

|

Leica ALS50-II |

SICK LMS151 |

|

Data generation rate |

Measurements / s |

150 000 |

27 000 |

|

Area covered |

m2 / s |

37 500 |

80 |

|

Horizontal resolution |

m |

1 |

0.012 |

|

Horizontal accuracy |

cm |

±80cm |

±7cm |

|

Vertical resolution |

m |

0.5 |

0.012 |

|

Vertical accuracy |

cm |

±30cm |

±4cm |

Table 5: Comparison of aerial and

terrestrial LiDAR systems (values are approximate)

For PV, the terrestrial LiDAR system clearly offers a

comprehensive package for precisely locating items of interest. Further

developments in processing the point clouds will lead to estimation of

yield throughout a block and thereby facilitating implementation of

performance adjusting measures to standardise the yield and achieve

higher returns. For example, a mulch delivery machine could have its

outflow rate adjusted according to its GPS position, allowing the driver

to concentrate on driving instead of controlling the mulch delivery

rate. This not only reduces the amount of excess mulch used but reduces

the operator’s workload, with less likelihood of error such as collision

with the vines due to fatigue.

5. CONCLUSION

In this paper we have evaluated several state-of-the-art

geospatial technologies for precision viticulture including

multi-layered information systems, GNSS receivers, Continuously

Operating Reference Stations (CORS) and related hardware. These

technologies were demonstrated to support sustainable farming practices

including organic and biodynamic principles but require further work

before their use can be widely adopted. Limitations of the current

systems were identified in ease-of-use and more particularly in the lack

of a unified data management system which combines field and office use.

While individual technologies such as GIS, GNSS and handheld computers

exist, their integration with existing geospatial information requires

the expertise of geospatial professionals, and closer collaboration with

end users.

In addition we demonstrated the application of an

unmanned ground vehicle which produced centimetre-level feature position

estimation through a combination of terrestrial LiDAR mapping and GNSS

localisation. We compared the accuracy of this mapping approach with

aerial LiDAR imagery of the vineyard and showed that apart from coverage

rate the terrestrial approach was more suited in precision viticulture

applications. Future work will focus in integrating this approach with

precision viticulture machinery for estimating yield and controlling

yield-dependent variables such as variable mulching, irrigation,

spraying and harvesting. The end product? Spatially smart wine.

ACKNOWLEDGEMENTS

The authors wish to acknowledge the following bodies and

individuals who provided equipment and support: Land and Property

Management Authority (in particular Glenn Jones), CR Kennedy (in

particular Nicole Fourez), ESRI Australia and the University of New

South Wales. Particular thanks go to the vineyard owner and manager,

Justin Jarrett and family.

REFERENCES

-

ARNÓ, J., MARTÍNEZ-CASASNOVAS, J., RIBES-DASI, M. &

ROSELL, J. (2009) Review. Precision Viticulture. Research topics,

challenges and opportunities in site-specific vineyard management.

Spanish Journal of Agricultural Research, 7, 779-790.

-

BATTAGLINI, A., BARBEAU, G., BINDI, M. & BADECK, F.

W. (2009) European winegrowers’ perceptions of climate change impact

and options for adaptation. Regional Environmental Change, 9, 61-73.

-

BRAMLEY, R. (2009) Lessons from nearly 20 years of

Precision Agriculture research, development, and adoption as a guide

to its appropriate application. Crop and Pasture Science, 60,

197-217.

-

BRAMLEY, R., PROFFITT, A., HINZE, C., PEARSE, B.,

HAMILTON, R. & STAFFORD, J. (2005) Generating benefits from

precision viticulture through selective harvesting. Wageningen

Academic Publishers.

-

BRAMLEY, R. & ROBERT, P. (2003) Precision

viticulture-tools to optimise winegrape production in a difficult

landscape. American Society of Agronomy.

-

CHAOUI, H. I. & SØRENSEN, C. G. (2008) Review of

Technological Advances and Technological Needs in Ecological

Agriculture (Organic Farming).

-

DEDOUSIS, A. P., BARTZANAS, T., FOUNTAS, S., GEMTOS,

T. A. & BLACKMORE, S. (2010 ) Robotics and Sustainability in Soil

Engineering. Soil Engineering. Springer Berlin Heidelberg.

DELMAS, M. A. & GRANT, L. E. (2008) Eco-labeling strategies: the

eco-premium puzzle in the wine industry.

-

FAIRLIE, K. & MCALISTER, C. (2011) Spatially Smart

Wine - Getting Young Surveyors to Network in the Vineyard! And other

Australian young surveyor activities. . International Federation of

Surveyors Working Week 2011. Marrakech, Morocco.

-

GEBBERS, R. & ADAMCHUK, V. I. (2010) Precision

Agriculture and Food Security. Science, 327, 828-831.

-

GIL, E. (2007) Variable rate application of plant

protection products in vineyard using ultrasonic sensors. Crop

Protection, 26, 1287-1297.

-

GRIFT, T., ZHANG, Q., KONDO, N. & TING, K. (2008) A

review of automation and robotics for the bioindustry. Journal of

Biomechatronics Engineering, 1, 37-54.

-

GROTE, K., HUBBARD, S. & RUBIN, Y. (2003)

Field-scale estimation of volumetric water content using

ground-penetrating radar ground wave techniques. Water Resour. Res,

39, 1321.

-

GUIVANT, J. E. (2008) Real Time Synthesis of 3D

Images Based on Low Cost Laser Scanner on a Moving Vehicle. V

Jornadas Argentinas de Robotica, Bahia Blanca.

-

HALL, A., LOUIS, J. & LAMB, D. (2003) Characterising

and mapping vineyard canopy using high-spatial-resolution aerial

multispectral images. Computers & Geosciences, 29, 813-822.

-

JOHNSON, L., ROCZEN, D., YOUKHANA, S., NEMANI, R. &

BOSCH, D. (2003) Mapping vineyard leaf area with multispectral

satellite imagery. Computers and Electronics in Agriculture, 38,

33-44.

-

KATZ, R., MELKUMYAN, N., GUIVANT, J., BAILEY, T. &

NEBOT, E. (2005) 3D sensing framework for outdoor navigation.

Australian Conference on Robotics and Automation (ACRA), Proceedings

of. Citeseer.

-

KEIGHTLEY, K. E. & BAWDEN, G. W. (2010) 3D

volumetric modeling of grapevine biomass using Tripod LiDAR.

Computers and Electronics in Agriculture, 74, 305-312.

-

KIRCHMANN, H. (1994) Biological dynamic farming—An

occult form of alternative agriculture? Journal of Agricultural and

Environmental Ethics, 7, 173-187.

-

LAMB, D., BRAMLEY, R. & HALL, A. (2002) Precision

viticulture-an Australian perspective. ISHS.

-

LEICA GEOSYSTEMS (2009) Leica Zeno 10 & Zeno 15.

-

LONGO, D., PENNISI, A., BONSIGNORE, R., MUSCATO, G.

& SCHILLACI, G. (2010) A Multifunctional Tracked Vehicle Able to

Operate in Vineyards Using GPS and Laser Range-finder Technology.

International Conference Ragusa SHWA2010 - September 16-18 2010

Ragusa Ibla Campus - Italy "Work safety and risk prevention in

agro-food and forest systems".

-

LÓPEZ RIQUELME, J., SOTO, F., SUARDÍAZ, J., SÁNCHEZ,

P., IBORRA, A. & VERA, J. (2009) Wireless sensor networks for

precision horticulture in Southern Spain. Computers and Electronics

in Agriculture, 68, 25-35.

-

MATESE, A., DI GENNARO, S., ZALDEI, A., GENESIO, L.

& VACCARI, F. (2009) A wireless sensor network for precision

viticulture: The NAV system. Computers and Electronics in

Agriculture, 69, 51-58.

-

MAZZETTO, F., CALCANTE, A., MENA, A. & VERCESI, A.

(2010) Integration of optical and analogue sensors for monitoring

canopy health and vigour in precision viticulture. Precision

Agriculture, 1-14.

-

MCBRATNEY, A., WHELAN, B., ANCEV, T. & BOUMA, J.

(2005) Future directions of precision agriculture. Precision

Agriculture, 6, 7-23.

-

MORAIS, R., FERNANDES, M. A., MATOS, S. G., SER DIO,

C., FERREIRA, P. & REIS, M. (2008) A ZigBee multi-powered wireless

acquisition device for remote sensing applications in precision

viticulture. Computers and Electronics in Agriculture, 62, 94-106.

-

PROFFITT, T. (2006) Precision viticulture: a new era

in vineyard management and wine production, Winetitles.

-

REEVE, J. R., CARPENTER-BOGGS, L., REGANOLD, J. P.,

YORK, A. L., MCGOURTY, G. & MCCLOSKEY, L. P. (2005) Soil and

winegrape quality in biodynamically and organically managed

vineyards. American journal of enology and viticulture, 56, 367.

-

ROSELL, J. R., LLORENS, J., SANZ, R., ARNÓ, J.,

RIBES-DASI, M. & MASIP, J. (2009) Obtaining the three-dimensional

structure of tree orchards from remote 2D terrestrial LIDAR

scanning. Agricultural and Forest Meteorology, 149, 1505-1515.

-

ROSELL POLO, J. R., SANZ, R., LLORENS, J., ARNÓ, J.,

ESCOL , A., RIBES-DASI, M., MASIP, J., CAMP, F., GR CIA, F. &

SOLANELLES, F. (2009) A tractor-mounted scanning LIDAR for the

non-destructive measurement of vegetative volume and surface area of

tree-row plantations: A comparison with conventional destructive

measurements. Biosystems Engineering, 102, 128-134.

-

ROWBOTTOM, B., HILL, M., VALLEY, Y., HEATHCOTE, B. &

STRATHBOGIE, B. (2008) Managing the nutrition of grapevines.

Australian viticulture, 12, 85.

-

SHANMUGANTHAN, S., GHOBAKHLOU, A. & SALLIS, P.

(2008) Sensor data acquisition for climate change modelling. WSEAS

Transactions on Circuits and Systems, 7, 942-952.

-

SHI, L., MIAO, Q. & JINGLIN, D. (2008) Architecture

of Wireless Sensor Networks for Environmental Monitoring. Education

Technology and Training, 2008. and 2008 International Workshop on

Geoscience and Remote Sensing. ETT and GRS 2008. International

Workshop on.

SIEGFRIED, W., VIRET, O., HUBER, B. & WOHLHAUSER, R. (2007) Dosage

of plant protection products adapted to leaf area index in

viticulture. Crop Protection, 26, 73-82.

-

TURINEK, M., GROBELNIK-MLAKAR, S., BAVEC, M. &

BAVEC, F. (2009) Biodynamic agriculture research progress and

priorities. Renewable Agriculture and Food Systems, 24, 146-154.

-

WHITTY, M., COSSELL, S., DANG, K. S., GUIVANT, J. &

KATUPITIYA, J. (2010) Autonomous Navigation using a Real-Time 3D

Point Cloud. 2010 Australasian Conference on Robotics and

Automation. 1-3 December 2010 Brisbane, Australia.

BIOGRAPHICAL NOTES

Spatially Smart Wine was a project initiated by

an enthusiastic group of Sydney Young Surveyors, with the support

of the Institute of Surveyors New South Wales and the School

of Surveying and Spatial Information Systems and the University

of New South Wales. The intent of the group is to provide informal

networking and professional development opportunities for surveyors in

the Sydney region.

The Mechatronics group in the School of Mechanical and

Manufacturing Engineering at the University of New South Wales,

Australia conducts research in the preeminent Faculty of Engineering in

Australia. Research is conducted into mobile robotics solutions

primarily for agricultural automation but also for the defence and

mining industries. The research includes advanced control systems, image

processing, terrain mapping, aerial vehicle dynamics, advanced sensor

data fusion, path planning, motion planning and navigation. The group is

equipped with a wide range of unmanned systems, ranging from very small

ground vehicles and aerial vehicles to commercially available large

scale machines that have been retrofitted for autonomous operation. In

addition the group also undertakes complex, large scale system

development.

Kate FAIRLIE, New South Wales Young Surveyors and

Chair of FIG Young Surveyors

Adrian WHITE , New South Wales Young Surveyors

Mitchell LEACH, New South Wales Young Surveyors

Fadhillah NORZAHARI, New South Wales Young Surveyors

Mark WHITTY, School of Mechanical and Manufacturing Engineering,

University of New South Wales, Australia

Stephen COSSELL, School of Mechanical and Manufacturing

Engineering, University of New South Wales, Australia

Jose GUIVANT, School of Mechanical and Manufacturing Engineering,

University of New South Wales, Australia

Jayantha KATUPITIYA, School of Mechanical and Manufacturing

Engineering, University of New South Wales, Australia

CONTACTS

Ms Kate FAIRLIE

University of Technology, Sydney

Chair, FIG Young Surveyors Network

kfairlie@gmail.com

Mr Mark WHITTY

School of Mechanical and Manufacturing Engineering,

University of New South Wales, AUSTRALIA

m.whitty@gmail.com

|