Article of the Month -

August 2010

|

Terrestrial Laser Scanning for Mainstream Land Surveying

Mike PINKERTON, New Zealand

This article in .pdf-format (10

pages, 5.51 MB)

This article in .pdf-format (10

pages, 5.51 MB)

1) This paper has been prepared and presented at

the FIG Congress 2010 in Sydney, Australia, 11-16 April 2010. This paper

provides a good introduction for those who are thinking about the

question whether to invest in laser scanning.

Handouts of this presentation as a .pdf file.

SUMMARY

Terrestrial Laser Scanning is quite legitimately starting to take a

larger stake in the domain of mainstream land surveying. This

technological advancement is similar in significance for the industry to

what RTK GPS was doing a decade or so ago, and it seems only logical

that over the next decade 3D scanning technology will evolve into a

mainstream tool in the arsenal of most land surveying organizations.

This paper overviews some typical projects where Terrestrial Laser

Scanning is changing peoples perceptions of the complexity, accuracy and

efficiency in which spatial data can be captured by the modern surveyor.

The examples are presented in easily digestible overview format,

including the benefits and limitations encountered.

1. INTRODUCTION

Towards the latter half of the 1990’s I was embarking on the early

stages of my professional surveying career. At that stage real time

kinematic GPS was starting to emerge as the latest and greatest in the

world of conventional surveying, following on from the success of

post-processed GPS which had revolutionized certain measurement

applications, but had failed to capture the imagination of many in

mainstream topographical surveying. Within that field surveyors have

traditionally been cautious when it comes to adopting new technologies;

after all in many cases the tried and tested methods covered their

requirements for long periods of time.

Being a young, carefree, globe trotting surveyor, I soon realized the

potential in using RTK GPS and pushed the case for hiring it in for

project work where it had clear benefits. This soon evolved to working

freelance chasing project work which utilized the technology. The

factors that contributed towards to the slow uptake of this technology

by the mainstream land surveying industry were apparent for all to see:

- Lack of understanding of the potential applications (by both

surveyors and their clients);

- Lack of understanding about the benefits

- Lack of understanding about the limitations

- Lack of personnel trained in the use of the equipment

- High capital outlay required for the technology

The end result was that using traditional tried and tested techniques

were often the fall back position. However over the last decade the

above factors have slowly been mitigated, to a point where RTK GPS (or

its modern derivatives such as Network GNSS) have become commonplace, if

not indispensible in our industry.

When I first saw laser scanning in action a couple of years ago, I

saw many parallels to what I had witnessed in the 1990’s with GPS. Laser

scanning was not in its infancy, it had been carving out a niche in

certain spatial applications for well over a decade. However it was, in

my opinion, on the verge of breaking out as a serious contender in the

field of mainstream surveying. The familiar obstacles, as listed above

as items 1 to 5, lay in its way. It seemed only logical to me that the

next 5 years would see similar infiltration to a point where scanning

will become a mainstream tool in the land surveying industry.

This paper examines some recent examples to illustrate where the

technology is currently being put to good use within the surveying

discipline of Aurecon in Australasia.

2. DIGITAL TERRAIN MODELLING APPLICATIONS

In large open areas which require efficiency of data collection at a

level of accuracy not obtainable by LiDAR (or a scale where the cost of

LiDAR can not be justified), TLS is a very viable option, and have the

added bonus of being able to produce some nice looking outputs to go

along with the standard deliverables such as contour models and volume

calculations.

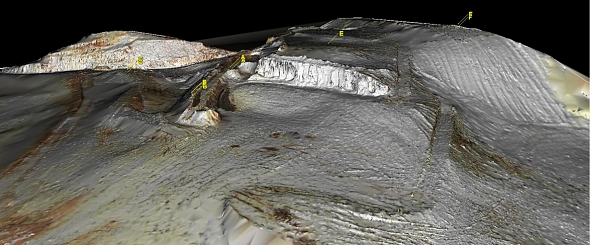

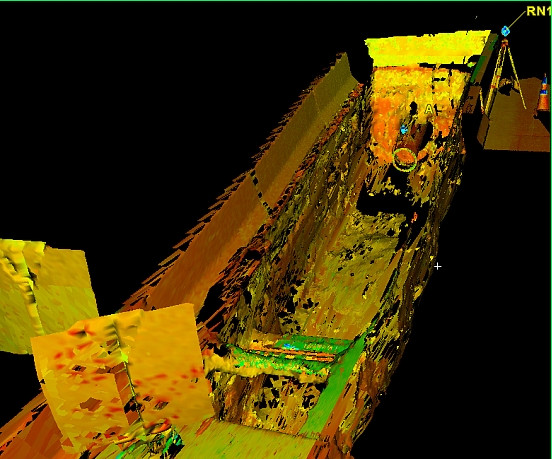

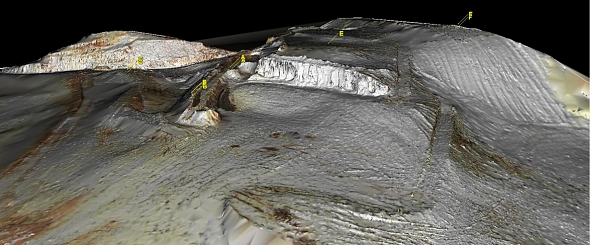

2.1 Example 1: Earthworks Stock take Volumes: Tauriko Land

Development, Tauranga New Zealand

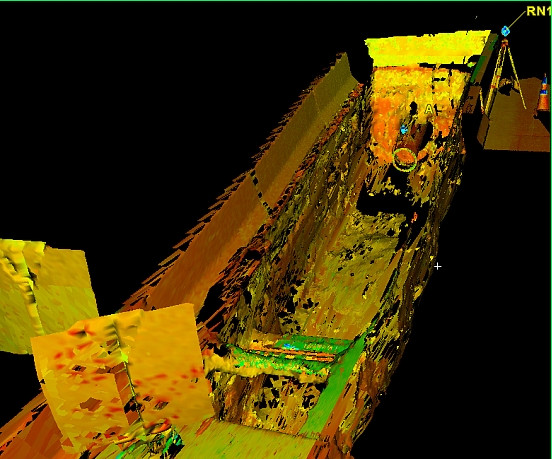

Overview of the 3D model of the Earthworks site.

Project Overview:

7ha earthworks site, Tauriko Industrial Estate Stage 2, Tauranga, New

Zealand.

Purpose of Survey:

Creation of digital terrain model to calculate volume of earth

excavated since beginning of current earthworks season (surface

comparison).

Scanning Method:

Scanning from vantage points around the site: 8 setups used over 7 ha

area, with scan targets used to merge individual scans together. Target

points were coordinated concurrently by RTK GPS to coordinate scan in

terms of project control. Total 5 hours on site (2 surveyors used)

including a cross section surveyed by GPS to verify scan model

Traditional Method:

RTK GPS, typically 3 days surveying by 1 surveyor, with the ground

model generalized by major changes of grade and sampled spot heights.

Potential health and safety hazards include the surveyor walking around

live excavation areas and having to walk close to the top of steep

embankments to capture the change of grade string.

|

|

|

Scanning in operation during the excavation

of one of the areas, and the resulting gound model (decimated) |

Benefits of Scanning:

- Far more accurate detail captured for the ground model;

- Scanning undertaken whilst plant operating on site (earthmoving

machines later removed from the scan model using Lowest Returning

Signal algorithms);

- Minimal exposure to the largest Health and Safety risks on site:

moving plant and falls from height;

- Saving on site work meant the stock take volume could be

captured within 1 day;

- 3D visualization was used to bring the site to life on the

computer screen for the project managers.

Limitations:

- Scan model typically a few cm above GPS model because scan model

more likely to capture high points in uneven ground, and GPS pole

typically penetrates surface slightly

- Scanning would have been more difficult in marginal weather.

- A couple of minor shadow areas existed in the model where detail

was not as complete as the rest of the model

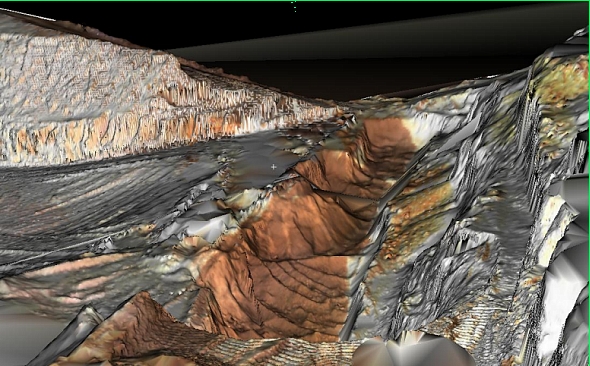

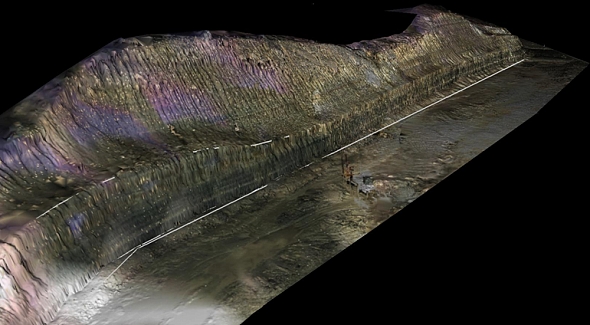

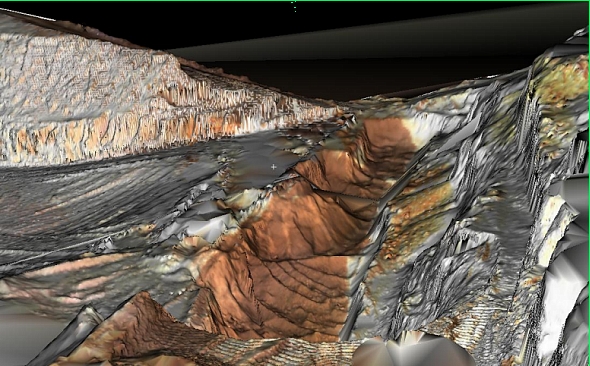

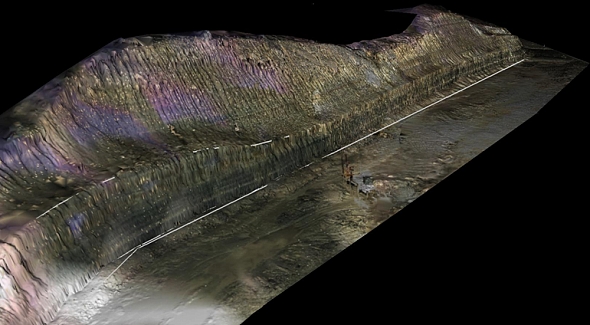

2.2 Example 2: Highwall at Centennial Mine, Airly, New South

Wales, Australia

Project Overview:

500m of highwall (in 2 locations) as part of a topographical survey

of the subject site.

Purpose of Survey:

Supply of detailed ground information for site prior to the

commencement of excavation for the coal seam drilling.

Scanning Method:

Scanning from 5 locations on the embankment, merged into 1 digital

terrain model decimated to an average of 1 point per 0.5m, then exported

to be processed in 12D along with the topographical detail captured on

the rest of the site. Total time on site was less than 1 day, including

site induction requirements.

Traditional Method:

In the preliminary survey of the site, reflectorless total station

measurements were taken at various locations along the high wall to

model the general slope. For safety reasons, no personnel were allowed

on or above the highwall without specialist equipment and training,

along with a task specific safety plan.

Benefits of Scanning:

- Efficiency of data capture incorporating a higher level of

detail;

- No requirement to access on, above or below the wall

- Effective 3D visualisation created of the survey as a bonus

delivery to the client

Limitations:

- Not all vegetation removed automatically by the processing of

the ground mesh therefore quite a few data spikes had to be taken

out manually;

- Some areas were heavily eroded with deep ruts (which would

typically be ignored by a surveyor) so the decimated ground model

was quite spiky in some areas on the bank, however decimation had to

be applied to ensure the ground model file was not too large to be

handled by other software.

|

|

|

Overview of the site and resulting gound

model |

3. CIVIL INFRASTRUCTURE

Through the recent economic downturn it has been general

infrastructure work that has kept many firms in business as governments

sought to buy their way out of recession through investment in various

projects. As firms look for a competitive edge, the use of laser

scanning can provide not just a point of difference but a smarter more

innovative way of approaching many of the spatial requirements of these

projects.

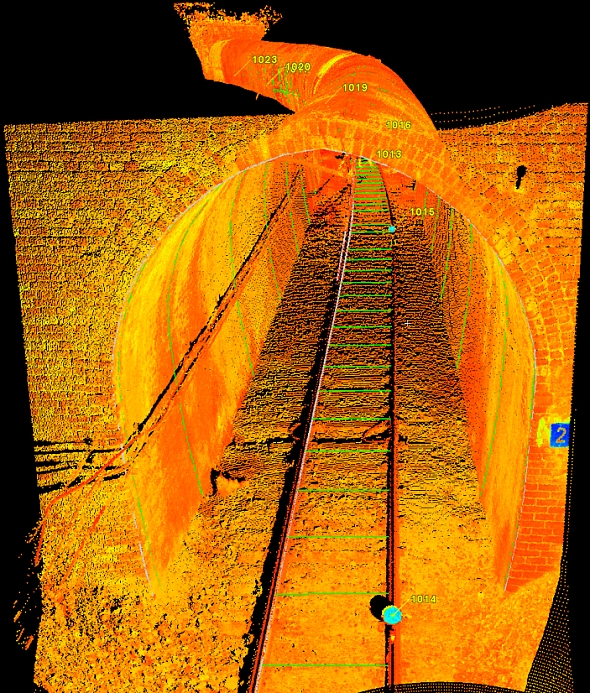

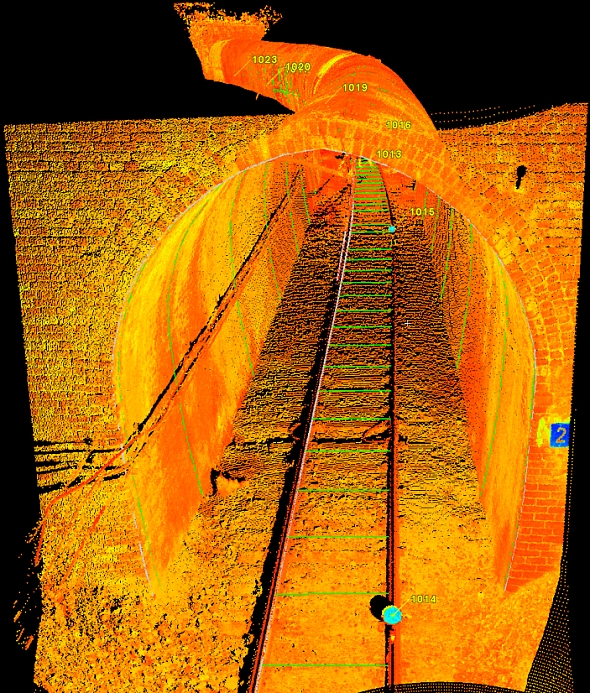

3.1 Example 3: Johnsonville Rail Tunnel Upgrade, Wellington, New

Zealand

Project Overview:

Over the course of 2008 Aurecon (formerly Connell Wagner) was

commissioned to work on the Johnsonville Rail Upgrade project to develop

a new highly optimised track alignment through seven horseshoe shaped,

brick lined, tunnels which were more than 100 years old. Each tunnel was

between 100-200m long.

Purpose of Survey:

The goal was to enable significantly larger passenger trains to pass

through with a minimum amount of modification work to the tunnels. The

spatial modelling approach developed by Aurecon utilised laser scanning

technology to build 3D models of the tunnels to the requisite accuracy

to be utilised in the rail alignment redesign and clearance modelling.

Scanning Method:

The scanner was used to ”Traverse” through each tunnel with a setup

just outside each portal, and an average of one setup per 60-100m inside

the tunnel (depending on curvature). All scanning was conducted at night

during a 5 hour line shut down period at an average of between 1 and 2

tunnels per night. Resulting point cloud models were reduced to cross

sections at between 1 and 4 m intervals (depending on curvature)

including inside running edge of rails, overhead wire position, and

minimum clearance to tunnel wall.

Traditional Method:

Prior to laser scanning I would have carried out a job like this by

traversing through the tunnel and capturing cross sectional shapes using

reflectorless total station (probably using someone with a laser pointer

to scribe out each section on the wall so that you could see where you

were pointing), or alternatively that person holding a prism on the wall

at each measurement location (and thus requiring the overhead wire to be

turned off). This is a very slow method if considering the level of

detail required on this project, and does not guarantee that you are

always capturing the wall at the point of minimum clearance.

Benefits of Scanning:

- Efficiency of data capture far exceeds any conventional method;

- Accuracy of tunnel modelling estimated at +/-20mm at the 95%

confidence level at any location in the tunnel relative to the fixed

survey control points;

- No downside about working at night in poor lighting conditions.

|

|

|

Typical scanner setup and resulting view of

the point cloud (with some modelled elements shown in green) |

Limitations:

- Some damp areas of tunnel walls resulted in extra setups being

required closer to the damp areas;

- Processing time was quite labour intensive to extract clearance

sectioning in the required format because scan software provided no

functionality in this regard.

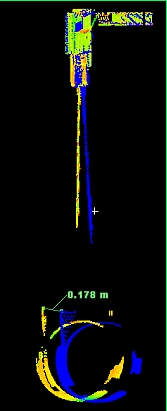

3.2 Example 4: Watermain Upgrade and Pipe Replacement, Auckland,

New Zealand

Project Overview:

Modification of prefabricated polyethylene pipe which did not fit the

bend it was designed for.

Purpose of Survey:

The open excavation of the pipe bend location was in the middle of a

major urban arterial road in the city. However the prefabricated pipe

did not fit the excavated curve and therefore the spatial location and

the direction of the pipes ends at the extremities of the excavation

were required, in addition to the shape of the prefabricated pipe lying

nearby the site. Once this information was captured an iterative

approach with the contractor was undertaken to derive the preferred

modifications to the existing pipe using the resources they had on site,

achieving a shape that could be coupled to the existing pipes, and could

be installed clear of the existing utility services in the trench.

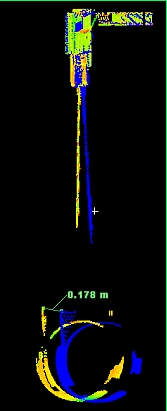

Scanning Method:

2 Scanner setups were used to capture the trench details (1 on the

floor of the trench, and 1 just above one end), and 2 scanner setups

were used to capture the shape of the prefabricated pipe. All the

pipework on site modelled as spatial elements within Cyclone software

was then imported into AutoCAD for spatial manipulation and drawing

outputs for the contractor.

Traditional Method:

A double prism pole would be used to capture the spatial location of

the existing pipework within the confines of the trench, as well as the

prefabricated pipe shape, however the risk of any proposed modification

still resulting in a misfit, or clash with any other elements in the

trench meant that the laser scanning could be easily justified in this

case.

Benefits of Scanning:

- Rapid and complete data capture within the confined space of the

existing trench

- Complete and accurate modelling of the prefabricated section of

pipe

- 3D virtual modelling of the pipe modification to prove the

solution would work on site

Limitations:

- The cost of the solution to the client was slightly higher that

conventional methods therefore the value of the risk mitigation had

to be justified;

- Bulky equipment (including cables, laptop and battery) to move

in and out of trench.

Meshed view of one end of the excavation trench.

4. PLANT AND INDUSTRIAL APPLICATIONS

This has traditionally been the field where laser scanning has

developed over the past 10 years, as surveyors and engineers are often

called on to provide spatial measurements in complex environments. Where

as conventionally one might provide distinct measurements at various

locations (maybe cross referenced against photographs), laser scanning

can be a viable option where more complete information is required, or

limitations exist regarding the ability to make direct measurements.

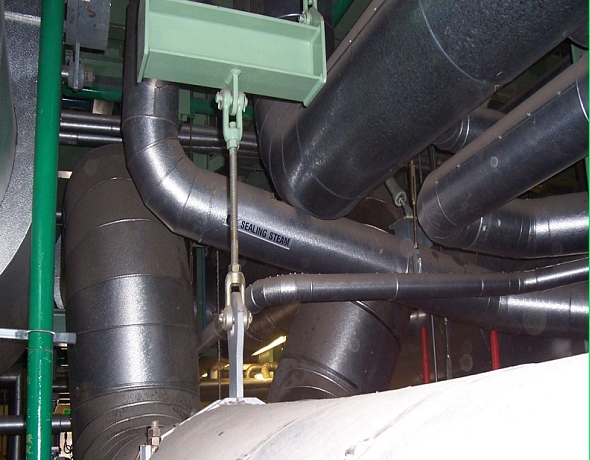

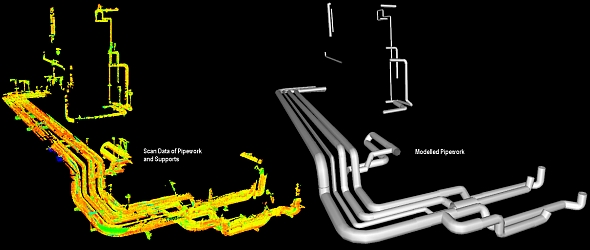

4.1 Example 5: Pipe Expansion Deformation, Swanbank PowerStation,

Queensland, Australia

Project Overview:

Modelling of the High Pressure, Low Pressure, Cold Reheat, and Hot

Reheat pipework between the steam generators and the turbines.

Purpose of Survey:

Measure the deformation of main steam pipework between shutdown

(cold) and running (hot) conditions to cross check against expected

movements, as well as provide as-built drawings of the pipework

dimensions.

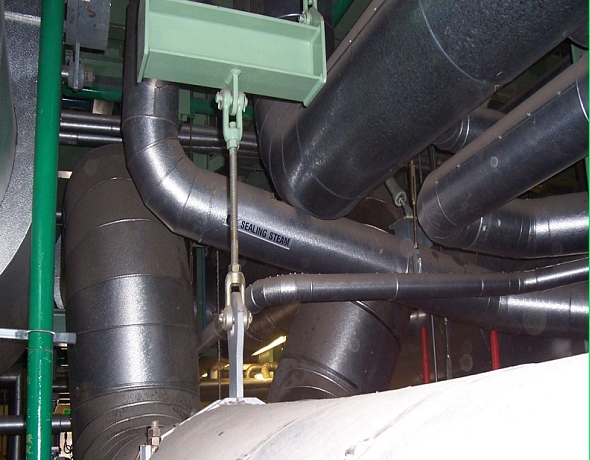

Typical view of the complexity of pipework around which the 4 main pipes

weave.

Scanning Method:

32 to 36 scanner setups over 3 days were used during each of the two

surveys to capture enough data on the four pipes, including their

accurate locations at each of the support points. Pipe movements were up

to 200mm between hot and cold positions. Adhesive scan targets were

installed on walls and beams to provide control between the 2 scans, and

residuals on these marks were typically less than 5mm between the two

surveys. Pipe positions were compared at each of the support points to

derive

DX,

DY

& DZ

values between the two surveys, to an estimated accuracy of +/- 5mm (1

s.d.).

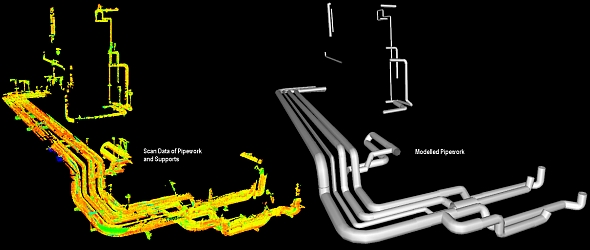

Overview of the point cloud data and modelled pipework following the

cold scan data capture

|

Typical comparisons between cold and hot scan positions. |

Traditional Method: Movements have traditionally

been measured by the installation of fixed targets (often

painted on the pipes) to measure the movement at distinct

locations. Some support points allow direct measurement at that

location (e.g. a sliding plate joint, or a spring loaded lower

support). The lack of as-built drawings for even modern plant is

testament to the fact that creation of these drawings is not a

straight forward surveying task in most cases and drawings are

often left incomplete.

Benefits of Scanning:

- Efficiency of data capture

- Completeness of data capture

- Mitigation of the risk to need to revisit the site for

additional measurements

Limitations:

- Many setups required to capture full 3D information in

areas often obstructed by plant or scaffold (in the case of

the cold survey conducted during the shut down period when

many other people were working on site). If only distinct

locations are chosen to measure they are often chosen in

locations which are easiest to see.

- Processing time is required to clean up scan data, model

pipework, and measure deformations from the scan model.

|

5. CONCLUSION

Highlighted in this paper are just a few examples of how Terrestrial

Laser Scanning solutions have been applied on projects where up until

very recently traditional surveying methods would have been the norm. As

more people are made aware of the benefits that laser scanning bring,

then their expectations from their spatial data suppliers will rise

accordingly. Concurrent with this change in attitude will be ongoing

further refinement of technology (both hardware and software). The end

result will be that laser scanning technology, like real time GPS did

before it, will inevitably become commonplace within the realm of

mainstream land surveying.

REFERENCES

All content within this paper have come from the personal experience

of the author.

Special thanks to Geoff Munns of Aurecon’s Auckland office for peer

review of this paper.

BIOGRAPHICAL NOTES

Mike Pinkerton (BSurv – Otago University; MNZIS) is a Senior

Surveyor based in Aurecon's Tauranga office and has over 13 years

professional experience within the surveying discipline. He has

extensive experience in the application of GPS and Laser Scanning in

surveying as well as working on large scale engineering and

topographical surveys in Australasia, Southeast and Central Asia, UK,

the Middle East and North Africa.

In his current role within the Survey discipline of Aurecon he

provides specialized input, support, and management for project work

across the Asia Pacific Region within Aurecon’s different market groups:

Community Infrastructure, Transport, Buildings, Water, Energy, Mining

and Industrial.

CONTACTS

Mr. Mike Pinkerton

Community Infrastructure

Aurecon

58 Cross Road, Sulphur Point

P. O. Box 2292

Tauranga

NEW ZEALAND

Tel. +64 21 378738

Fax +64 7 578 6143

Email:

pinkertonm@ap.aurecongroup.com

Web site: www.aurecongroup.com

|